Recent Post

Archive

- January 2026

- December 2025

- N Gauge LMS Period III 57ft Non Lavatory Suburban Stock - Progress Report II

- N Gauge Gresley Full Brake (BG) & Refurbished Buffet EP Update

- Dapol Personalised Christmas Wagons - Update

- N Gauge B17 4-6-0 Decorated Samples

- Dapol Christmas Opening Hours

- N Gauge LMS Period III 57ft Non Lavatory Suburban Stock

- November 2025

Dapol UK Production Investment

Dapol

Nov 13, 2025

Dapol UK Production Capability Grows Once More

Dapol's new CNC Tool station & Huw, Dapol's Master tool maker with two new bolster sets to work on

Dapol has established a strong reputation for manufacturing model railway products in the UK, having begun this journey back in 1983 in Winsford. Over the past decade, our commitment to becoming more self-sufficient has expanded in both scale and ambition.

We are thrilled to announce our latest investment aimed at enhancing our UK manufacturing capabilities. We have recently received our very own HURCO VM10HSi three-axis machining center, which marks a significant boost to our tool room's potential.

What's the purpose?

The Hurco VM10HSi three-axis machining center, will allow us to far enhance our ability to make our own tooling right here in the UK with greater speed and accuracy.

Interesting Facts

- LX, Y, Z Axis Travel: 660 x 406 c, 508 mm

- Table Size: 762 x 406 mm

- Maximum Weight on Table: 1,500 kg

- Maximum Spindle Speed: 20,000 rpm

- Maximum Number of Tools: 20 (all of which can be changed automatically by the machine)

- Precision: Accurate to one micron

The software we use is called Win Max. This allows our team to input exact instructions—either manually or through CAD input—for the machine to execute. Additionally, it provides the operator with a simulated preview of the upcoming process on the integrated monitor..

Progress so far

01.

The Hurco VM10HSi, still shiny and new after its initial installation. getting it in the tool shop was a bit of a challenge, fortunately our neighbors were kind enough to grant us access to our back door through their storage yard.

02.

The first cavity plate has been installed on the machining table and is being (VERY) accurately measured by a taster probe that is installed into the machine. As you can imagine everything has to be measured extremely accurately when you have to get multiple plates all to align perfectly and be able to hold in tons of force on the moulding machine.

03.

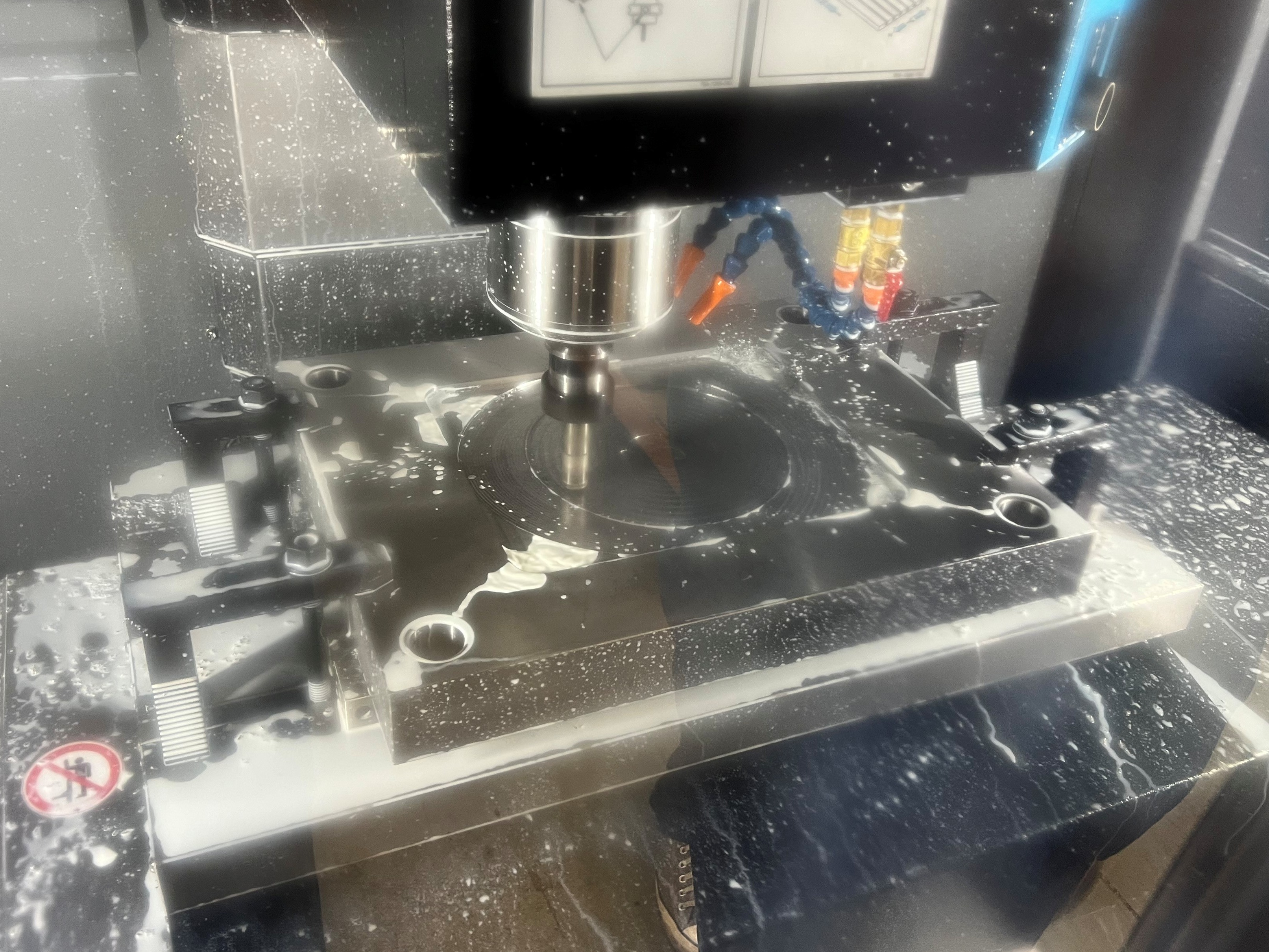

The very first cut being made in the cavity plate. A large (302.35x353.45x20.13mm) recess will be made into this 55mm thick piece of P20 Tool Steel. this recess will eventually receive the various inserts that are required for this particular project. The jet of white liquid you can see being aimed at the cut site is a water based milling fluid that keep both the metal plate being cut and the tool head cool.

04.

After only a short while you can see the recess starting to take shape in photograph number 4. It is quite mesmorising to stand and watch it in action as it removes layers of metal mm at a time.

05.

You can see the finished recess in the cavity plate. You may also notice four "pillars" sticking our, these are there to help guide all of the various plates together safely and make sure they all line up. Three if them are 32mm across and the forth is 30mm across.

having one pillar a different size keys the mould set in such a way that it can never be assembled the wrong way round.

06.

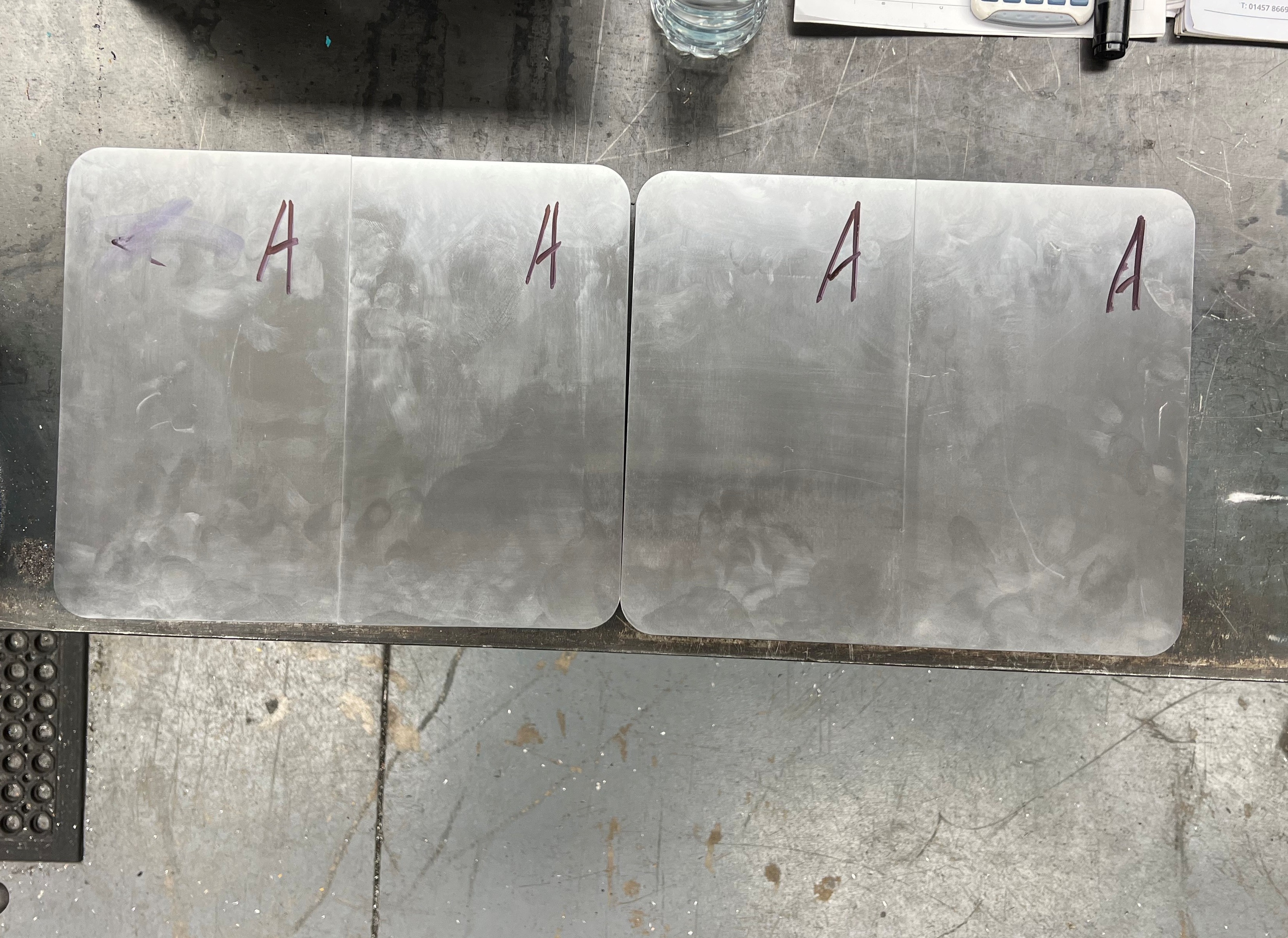

For those of you wondering what we will be putting in the recesses the team have been so carefully cutting out we have an image of our blank inserts. these are made from the same hardened P20 steel as the cavity plates.

These insert plates will eventually have the model details engraved into them and will be installed into the cavities that have been created.

← Older Post Newer Post →